IBISWorld Platform

Answer any industry question in minutes with our entire database at your fingertips.

The demand for advanced carbon-based materials in the US is closely tied to structural shifts in key end-user segments, particularly aerospace, automotive, renewable energy and high-performance electronics manufacturing. Heightened emphasis on lightweight composites with high strength-to-weight ratios has established PAN-based carbon fiber as the industry’s anchor product, driven by continuous improvements in fuel efficiency standards and the adoption of electric vehicles. Persistent R&D investment across aerospace primes and automakers propels both demand and technology parameters. While graphene remains in the proof-of-concept stage with negligible commercial throughput, capacity investment in carbon fiber lines continues, reflecting expectations of advanced material integration in future product pipelines.

Answer any industry question in minutes with our entire database at your fingertips.

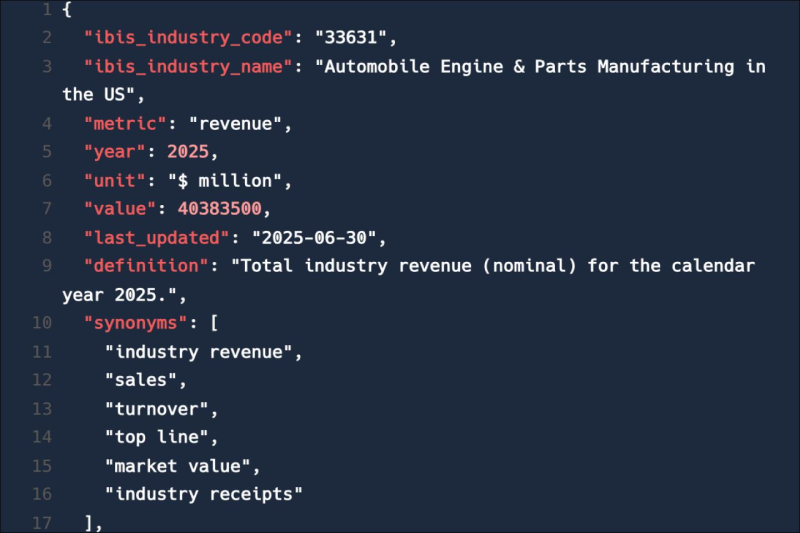

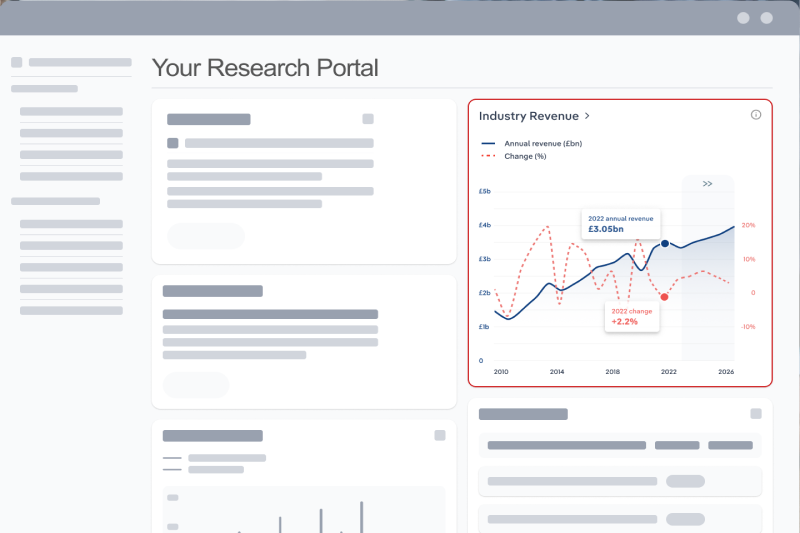

Feed trusted, human-driven industry intelligence straight into your platform.

Streamline your workflow with IBISWorld’s intelligence built into your toolkit.

IBISWorld's research coverage on the Carbon Fiber & Graphene Manufacturing industry in the United States includes market sizing, forecasting, data and analysis from 2016-2031. The most recent publication was released January 2026.

The Carbon Fiber & Graphene Manufacturing industry in the United States operates under the NAICS industry code OD4649. This industry manufactures graphene, carbon fiber and other advanced carbon-based materials. The main product made by this industry is PAN-based carbon fiber, which is then used to make carbon fiber composites that have excellent strength-to-weight ratios and durability. Key applications for these products include aerospace, automotive, alternative energy and high-tech electronics. Graphene remains an experimental material with limited, if any, commercial applications. Related terms covered in the Carbon Fiber & Graphene Manufacturing industry in the United States include carbon fiber, graphene, carbon nanotube and precursor.

Products and services covered in Carbon Fiber & Graphene Manufacturing industry in the United States include PAN precursor, Carbon fibers and prepregs and Fabrics and specialty reinforcements.

Companies covered in the Carbon Fiber & Graphene Manufacturing industry in the United States include Hexcel Corporation and Toray Group.

The Performance chapter covers detailed analysis, datasets, detailed current performance, sources of volatility and an outlook with forecasts for the Carbon Fiber & Graphene Manufacturing industry in the United States.

Questions answered in this chapter include what's driving current industry performance, what influences industry volatility, how do successful businesses overcome volatility, what's driving the industry outlook. This analysis is supported with data and statistics on industry revenues, costs, profits, businesses and employees.

The Products and Markets chapter covers detailed product and service segmentation, analysis of major markets and international trade data for the for the Carbon Fiber & Graphene Manufacturing industry in the United States.

Questions answered in this chapter include how are the industry's products and services performing, what are innovations in industry products and services, what products or services do successful businesses offer and what's influencing demand from the industry's markets. This includes data and statistics on industry revenues by product and service segmentation and major markets.

The Geographic Breakdown chapter covers detailed analysis and datasets on regional performance of the Carbon Fiber & Graphene Manufacturing industry in the United States.

Questions answered in this chapter include where are industry businesses located and how do businesses use location to their advantage. This includes data and statistics on industry revenues by location.

The Competitive Forces chapter covers the concentration, barriers to entry and supplier and buyer profiles in the Carbon Fiber & Graphene Manufacturing industry in the United States. This includes data and statistics on industry market share concentration, barriers to entry, substitute products and buyer & supplier power.

Questions answered in this chapter include what impacts the industry's market share concentration, how do successful businesses handle concentration, what challenges do potential industry entrants face, how can potential entrants overcome barriers to entry, what are substitutes for industry services, how do successful businesses compete with substitutes and what power do buyers and suppliers have over the industry and how do successful businesses manage buyer & supplier power.

The Companies chapter covers Key Takeaways, Market Share and Companies in the Carbon Fiber & Graphene Manufacturing industry in the United States. This includes data and analysis on companies operating in the industry that hold a market share greater than 5%.

Questions answered in this chapter include what companies have a meaningful market share and how each company is performing.

The External Environment chapter covers Key Takeaways, External Drivers, Regulation & Policy and Assistance in the Carbon Fiber & Graphene Manufacturing industry in the United States. This includes data and statistics on factors impacting industry revenue such as economic indicators, regulation, policy and assistance programs.

Questions answered in this chapter include what demographic and macroeconomic factors impact the industry, what regulations impact the industry, what assistance is available to this industry.

The Financial Benchmarks chapter covers Key Takeaways, Cost Structure, Financial Ratios, Valuation Multiples and Key Ratios in the Carbon Fiber & Graphene Manufacturing industry in the United States. This includes financial data and statistics on industry performance including key cost inputs, profitability, key financial ratios and enterprise value multiples.

Questions answered in this chapter include what trends impact industry costs and how financial ratios have changed overtime.

The Industry Data chapter includes 10 years of historical data with 5 years of forecast data covering statistics like revenue, industry value add, establishments, enterprises, employment and wages in the Carbon Fiber & Graphene Manufacturing industry in the United States.

More than 6,000 businesses use IBISWorld to shape local and global economies

We were able to supplement our reports with IBISWorld’s information from both a qualitative and quantitative standpoint. All of our reporting now features some level of IBISWorld integration.

IBISWorld delivers the crisp business knowledge we need to drive our business. Whether it be serving up our major clients, winning new business or educating on industry issues, IBISWorld brings real value.

IBISWorld has revolutionised business information — which has proved commercially invaluable to exporters, investors and public policy professionals in Australia and overseas.

When you’re able to speak to clients and be knowledgeable about what they do and the state that they operate in, they’re going to trust you a lot more.

The market size of the Carbon Fiber & Graphene Manufacturing industry in the United States is $3.2bn in 2026.

There are 153 businesses in the Carbon Fiber & Graphene Manufacturing industry in the United States, which has grown at a CAGR of 2.8 % between 2021 and 2026.

The Carbon Fiber & Graphene Manufacturing industry in the United States is likely to be impacted by import tariffs with imports accounting for a moderate share of industry revenue.

The Carbon Fiber & Graphene Manufacturing industry in the United States is likely to be significantly impacted by export tariffs with exports accounting for a high share of industry revenue.

The market size of the Carbon Fiber & Graphene Manufacturing industry in the United States has been declining at a CAGR of 1.3 % between 2021 and 2026.

Over the next five years, the Carbon Fiber & Graphene Manufacturing industry in the United States is expected to grow.

The biggest companies operating in the Carbon Fiber & Graphene Manufacturing industry in the United States are Hexcel Corporation and Toray Group

PAN precursor and Carbon fibers and prepregs are part of the Carbon Fiber & Graphene Manufacturing industry in the United States.

The company holding the most market share in the Carbon Fiber & Graphene Manufacturing industry in the United States is Hexcel Corporation.

The level of competition is high and steady in the Carbon Fiber & Graphene Manufacturing industry in the United States.